2026 Industrial Waste Management Playbook for Multi-Plant Operations

2026 Industrial Waste Management Playbook for Multi-Plant Operations

Multi-plant leaders ask the same question: how do we streamline waste disposal across multiple factory locations without sacrificing diversion or compliance? The answer is to treat waste as a logistics system with verifiable outcomes. This playbook lays out a practical, KPI-gated framework to standardize data, engineer diversion-first routing, verify downstream outlets, and phase in automation. It aligns operations with finance, tightens chain of custody, and reduces total system cost while de-risking compliance and service. Use it to create a single source of truth, optimize equipment and routes, and scale proven practices across your network. Recycler Routing Guide applies this logistics-first approach to multi-plant networks.

“Diversion-first routing” definition:

Diversion-first routing is a logistics design approach that prioritizes moving materials to recycling, reuse, or recovery outlets before landfill, engineered with route plans, containerization, and schedules that protect material quality and verified downstream compliance.

Executive summary

Three structural shifts are accelerating in 2026. First, responsibility is moving upstream to producers, who must “understand, monitor and evidence” waste outcomes via verifiable data. Second, digital traceability is becoming the default, with national trackers and cross-border systems. Third, AI is moving from pilots to deployment in safety, sorting, and quality control, raising expectations for risk reduction and throughput. Together, these shifts require standardized data, routings designed for diversion, and clean chain-of-custody evidence across every plant and supplier, not just the MRF or hub level (see the EU-focused overview of digital waste-tracking and accountability trends). Recycler Routing Guide centers on these requirements.

Headline actions to take:

- Establish a single source of truth (centralized waste ledger) and standardized taxonomy across all plants.

- Engineer diversion-first routing with verified downstream outlets and proof artifacts.

- Use transparent provider comparison and KPI-gated rollouts to control cost and risk.

- Integrate telemetry and national trackers; phase in AI for safety first, then quality and documentation automation.

Benefits: higher service reliability, stronger recovery and purity, lower total cost per ton, and audit-ready assurance.

Metrics snapshot to track:

- Diversion rate (by stream and plant).

- Cost per ton by stream (net of rebates).

- On-time service percentage and ticket closure time.

New accountability for producers

Responsibility for waste outcomes is shifting visibly upstream to producers, with stronger legal accountability and board-level visibility into waste data and end markets (see this 2026 waste-industry trends analysis). Extended Producer Responsibility (EPR) is a policy model that makes producers financially or operationally responsible for post-consumer product and packaging management through collection, treatment, and reporting obligations; it is expanding across Europe with increasingly granular data expectations (same source).

Move waste out of the “compliance-only” box by linking waste KPIs directly to production metrics and board dashboards so leaders evaluate diversion and contamination as performance levers, not just costs (as highlighted in industry trend briefings). Recycler Routing Guide treats diversion and contamination as controllable production metrics.

Digital traceability as the default

By 2026, many EU countries will run national digital waste-tracking systems, with cross-border frameworks emerging. Manual spreadsheets and PDF tickets will no longer suffice for multi-site chains of custody (see the EU digital waste-tracking outlook). Recycler Routing Guide uses a centralized ledger to standardize evidence across plants.

A practical flow:

- Capture at source: scan/load data at generation points and set-outs.

- Consolidate into a centralized waste ledger (your single source of truth).

- Bind supplier attestations and outlet certificates to event records.

- Sync event-level data to national trackers and cross-border systems.

Chain of custody is the documented, continuous record of material transfers from generation through processing and final disposition. Minimum data fields: material and subtype, weight (gross/net), timestamp, container ID, transporter ID, plant and geolocation, downstream outlet and permit, certificate ID, and operator/driver e-signature.

AI and automation in plant and network operations

AI has crossed from pilots to deployment. Vision systems now generate real-time waste flow intelligence; robotic sorters boost purity; and safety AI detects hazardous items like lithium-ion batteries to prevent fires (summarized in 2026 technology updates). Start with safety-first pilots (battery detection on pre-sort and tip floors), then scale to robotic sorting on high-volume lines and documentation automation for proof-of-service and certificates. Recycler Routing Guide prioritizes safety-first pilots before scaling.

Operator-reported gains indicate productivity and EBITDA uplift when automation is paired with process redesign and reliable data—a basis for ROI hypotheses and scenario planning (see Waste Management investor materials for automation-linked performance commentary).

Build a single source of truth for waste data

Multi-site control requires accurate standardized data and digital systems that support routing, reporting, and AI. Treat the waste ledger as a governed enterprise dataset. Build data hygiene routines (validation rules, exception queues), master data for streams, containers, providers, and outlets, and role-based access controls. In Recycler Routing Guide, the waste ledger is the backbone that ties routing, reporting, and assurance together.

Note that about 40% of enterprises cite data quality and governance as a top AI challenge; fix the foundation before model deployment (see the Guide to Next report). Design the schema around atomic events (pickup, weigh, transfer, process) with durable entity IDs (container, vehicle, provider, outlet) to enable queryable traceability and automated assurance.

Standardize waste taxonomy and measurement across plants

A standardized waste taxonomy is a controlled vocabulary and coding system that defines material families, subtypes, hazard flags, and quality grades, with crosswalks to regulatory codes (e.g., EWC), ensuring consistent naming, routing, pricing, and reporting across plants and suppliers.

Measurement hierarchy:

- Primary: certified scales with current calibration certificates.

- Secondary: calibrated container factors (by density/material) and haul weights.

- Exceptions: photo verification and supervisor sign-off; always record gross and net.

Sample table structure:

| Plant | Stream | EWC/NAICS | Container | Frequency | Avg Weight/Haul | Outlet | Certificate |

|---|---|---|---|---|---|---|---|

| Plant A | OCC | 15 01 01 | 40 yd compactor | 2x/week | 5.2 tons | MRF X | Cert-2026-001 |

| Plant B | Mixed Plastics | 12 01 05 | 30 yd roll-off | 1x/week | 2.8 tons | Reclaimer Y | Cert-2026-014 |

Map waste streams and logistics constraints

Build plant-by-plant maps of current flows:

- Generation points, contamination risks, container locations, access windows.

- Dock congestion times, internal transport equipment (tugs, forklifts), and queue durations.

- External constraints: vehicle access, axle/weight limits, shift schedules, site curfews.

Run time–motion studies on high-volume lines to identify quick wins: move staging to reduce cross-traffic, relocate compactors to cut internal haul time, tune baler throughput and bale changeover cadence. These changes often eliminate unnecessary pulls and reduce overflow risk.

Design diversion-first routing

“Diversion-first routing” definition:

Diversion-first routing is the deliberate engineering of collection circuits, containerization, and schedules to send materials first to recycling, reuse, or recovery—not landfill—while protecting material quality, certificates, and service reliability across every plant and consolidation node.

Practical steps:

- Segment routes by material quality sensitivity (e.g., dedicated OCC vs. mixed plastics).

- Assign dedicated circuits for high-purity streams; use consolidation hubs for low-volume sites.

- Lock outlet eligibility to verified downstreams with current certificates.

- Optimize sequence to minimize dwell time and contamination exposure.

- Simulate costs (distance, time, tips) and reliability (window compliance, backup routes).

- Publish SOPs and exception paths; train operators and providers.

Example route comparison:

| Route | Distance (mi) | Avg Dwell (hrs) | Contamination Risk | Cost/ton ($) |

|---|---|---|---|---|

| A: Direct OCC to MRF X | 46 | 1.2 | Low | 48 |

| B: OCC via Hub H1 | 39 | 3.0 | Medium (hub touch) | 44 |

| C: Mixed Plastics to Reclaimer Y | 58 | 2.4 | Medium | 72 |

This is the routing method at the core of Recycler Routing Guide.

Verify downstream outlets

Producers must be able to “understand, monitor and evidence” what happens downstream; verification is a compliance safeguard, not an option (see EU accountability overview). Verified downstream outlets are audited facilities with current permits, documented process capabilities, material specifications, traceable outputs, and certificates of processing tied to shipment events and chain-of-custody records. Recycler Routing Guide emphasizes shipment-linked certificates and event-level traceability.

Require an outlet verification packet containing:

- Permits and certifications; material specifications and acceptance criteria.

- Processing flow description and mass-balance approach.

- Audit cadence, exception handling, and corrective action process.

- Proof artifacts: weigh tickets, bills of lading, processing certificates with IDs.

Choose hub and spoke or on-site compaction

Trade-offs:

- Hub-and-spoke reduces haul frequency across small sites but adds transfer touchpoints and potential quality loss.

- On-site compaction increases payload density and reduces trips but requires capex, space, and maintenance.

Comparison inputs (consider energy-aware scheduling; electricity prices are projected to be ~4.5% higher in 2025 vs. 2024, affecting peak-hour operations windows per the Deloitte power and utilities outlook):

| Factor | Hub-and-Spoke | On-site Compaction |

|---|---|---|

| Site density | Ideal for many small, low-volume plants | Best for high-volume generators |

| Haul distance | Fewer long hauls, more regional shuttles | Fewer total trips; longer per pull |

| Stream mix | Mixed/variable streams | Stable, low-contamination streams |

| Touchpoints | More (added hub transfer) | Fewer (direct to outlet) |

| Uptime risk | Hub outages affect many plants | Compactor downtime affects one site |

| Power/peak pricing | Lower on-site energy demand | Requires grid capacity; schedule off-peak |

| Capex/Opex | Lower capex; hub fees | Higher capex; maintenance program |

Hybrid recommendation: compact high-volume, low-contamination streams onsite; route low-volume and variable streams through hubs aligned to diversion-first goals.

Right-size equipment and collection frequency

Sizing method:

- Calculate generation rate by shift and peak factors.

- Select container types per stream and contamination risk.

- Model service intervals to maintain 70–85% average fill.

Simple planning formula: pulls/week = (weekly volume ÷ container capacity) ÷ target utilization. Instrument compactors and roll-offs with telemetry to cut emergency pulls and optimize labor. Review seasonality and production schedules quarterly to adjust frequency and prevent overflow-driven contamination.

Integrate real-time telemetry and national trackers

With national digital waste-tracking widespread in Europe by 2026, design compliance-by-design integrations (see EU digital waste-tracking outlook). Data interface requirements:

- Secure API endpoints and webhook callbacks.

- Event timestamps, GPS/geofencing, and driver/operator e-signatures.

- Immutable hash logs and audit trails tied to certificates.

Integration plan:

- Sensor and telemetry mapping per asset.

- Gateway provisioning and network security.

- Platform-level event model aligned to your waste ledger.

- Adapter to national tracker schemas and cross-border data.

- Assurance dashboard with exception queues.

Flow: sensor → gateway → platform → national tracker → assurance dashboard. Recycler Routing Guide favors compliance-by-design integrations with event-level assurance.

Align KPIs with operations and finance

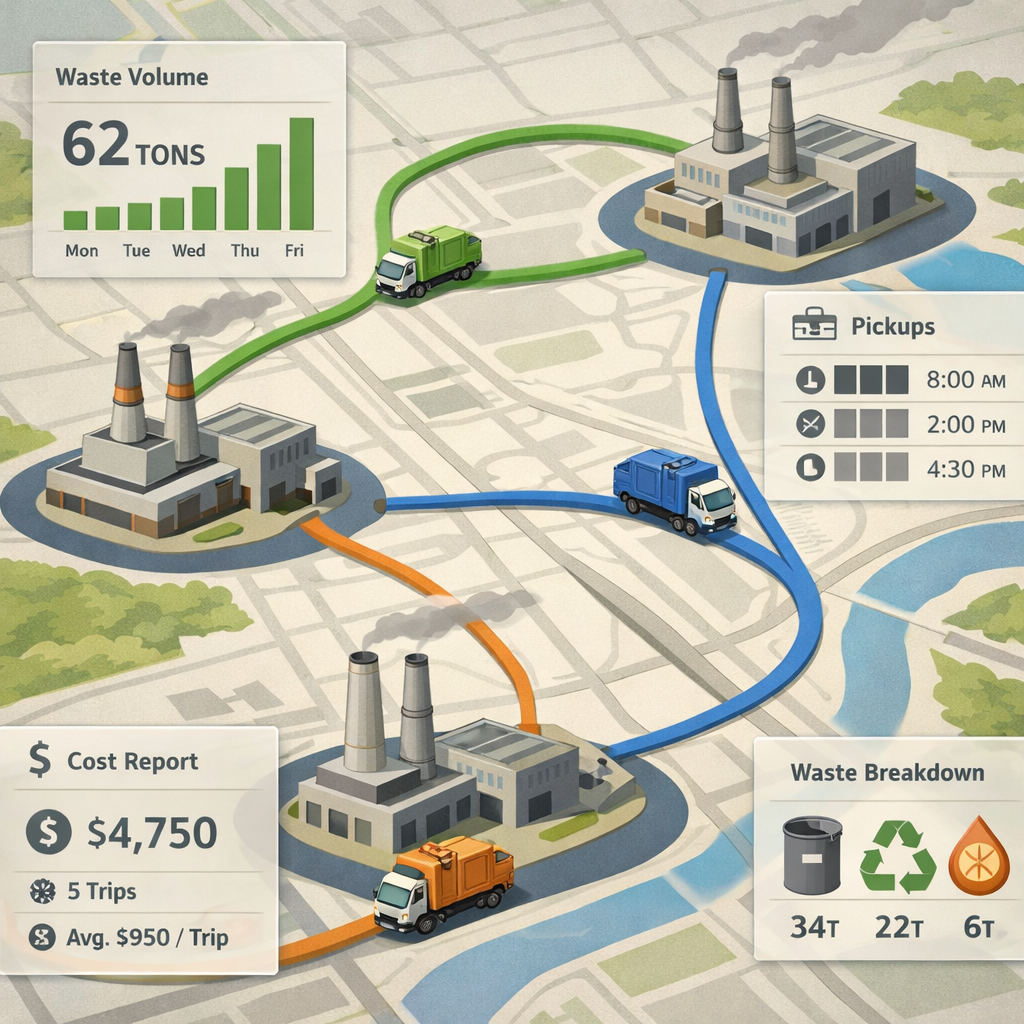

Waste data is moving into corporate governance and CSRD/ESRS-style reporting; align KPIs to board packs with assurance-ready evidence (see EU governance and reporting trends). Recommended KPI set:

- Diversion%, contamination%, cost/ton by stream.

- On-time service%, missed-pull recovery time.

- EBITDA impact from commodity uplift and rebates.

- Safety incidents prevented via AI detection.

Link these to production metrics (throughput, yield, changeover/downtime) so leaders can adjust routes, containerization, and staffing with shared targets. Recycler Routing Guide aligns operations and finance on these KPIs with assurance-ready evidence.

Transparent provider comparison and contracting

Build a plant-and-stream comparison matrix: on-time% SLA, proof-of-service artifacts, downstream verification packet, contamination handling, price floors/surcharges, fuel indices. Transparent provider comparison is a standardized evaluation method that normalizes scope, service levels, and full cost components—equipment, haul, disposal, rebates, and exception fees—so decisions reflect apples-to-apples reliability, diversion outcomes, and verified downstream compliance. Recycler Routing Guide advocates apples-to-apples matrices anchored in event-level data and certification requirements.

Contract requirements:

- Data-sharing clauses for event-level tickets and outlet certificates.

- API/EDI capabilities to feed your waste ledger and national trackers.

- Clear exception workflows, recovery SLAs, and surcharge indices.

For context on vendor selection dynamics, see this guidance on cost-effective nonhazardous waste removal companies.

Phased rollout with KPI gates

Minimize disruption with staged deployment:

- Pilot (2–3 plants): Gate to scale when on-time service ≥98%, certificates verified =100%, diversion uplift ≥10%.

- Phase 1 (regional cluster): Add cross-plant routing and telemetry; hold same gates plus <2% ticket exceptions.

- Phase 2 (network scale): Expand automation and cross-border syncing; maintain gates and publish quarterly assurance.

Include a RACI, change log, and runbooks for exceptions and escalation. Only scale AI/robotics after safety and purity targets are consistently met. Recycler Routing Guide uses KPI gates like these to de-risk scale-up.

Workforce safety and reskilling plan

Prioritize safety AI use cases—early detection of lithium-ion batteries and other ignition risks on tip floors and presort—before broader automation (see 2026 technology updates). Build a reskilling framework:

- Cross-train operators on sensors and compaction controls.

- Certify maintenance on new equipment and telemetry.

- Use eQMS workflows to reduce documentation time by about 10% (see Quality Digest webinars).

Safety KPIs: near-miss detection count, hazardous-item interception rate, lost-time incidents per 200k hours.

Governance and assurance for board reporting

Anticipate CSRD/ESRS-style reporting with external assurance; maintain audit-ready data trails and controls (see EU assurance expectations). Governance cadence:

- Monthly operations reviews (variance and corrective actions).

- Quarterly board packs (KPI trends, risk, compliance).

- Annual assurance cycle (independent testing of controls).

Implement structured data retention, role-based access, and change-management records in the waste ledger. This cadence mirrors practices recommended in Recycler Routing Guide.

M&A and network integration considerations

Waste sector M&A remains active; scale increasingly rewards digital capabilities and materials management discipline (see the waste management PE playbook). A 60–90 day integration checklist:

- Map data models; migrate to the enterprise waste ledger.

- Novate contracts; normalize SLAs and surcharge indices.

- Re-verify outlets; align certificates and audit cadence.

- Re-optimize routes; standardize safety systems and telemetry.

Risk matrix: stranded outlets (mitigate via pre-approved alternates), incompatible telemetry (deploy adapters), service disruption (dual-running and contingency carriers).

Economics and ROI modeling

Anchor decisions in unit economics and sensitivity analysis. Industry investments link automation to significant productivity gains and, in some facilities, more than doubling EBITDA margins when paired with process redesign (see Waste Management investor materials).

ROI template:

- Baseline cost/ton by stream and plant.

- Route redesign savings (miles, tips, time).

- Equipment capex/opex and maintenance; energy costs (peak/off-peak).

- Commodity revenue ranges (e.g., recycling $75–$150/ton; a $10 swing can materially impact net cost).

- Risk scenarios: energy price volatility, service failure penalties, contamination downgrades, labor reskilling costs.

Playbook timeline and milestones

A 12–18 month roadmap with gates:

| Quarter | Milestones | Decision Gates |

|---|---|---|

| Q1 | Data foundation: waste ledger live, taxonomy finalized, provider data onboarded | Data quality ≥98% validation pass |

| Q2 | Pilots at 2–3 plants; taxonomy rollout; outlet verification packets | On-time ≥98%, diversion +10%, certificates =100% |

| Q3 | Routing redesign; telemetry integrations; national tracker adapters | Provider APIs live across ≥80% plants |

| Q4+ | Automation scale (safety, quality); assurance prep and external testing | Outlet verification 100% for priority streams |

Critical path: data model → provider APIs → routing SOPs → telemetry → assurance.

Common pitfalls and corrective actions

- Inconsistent data: implement governance and master data stewardship; remember that 40% cite data quality as an AI barrier (Guide to Next).

- Overreliance on spreadsheets: migrate to a centralized waste ledger synced to national trackers (EU digital waste-tracking outlook).

- Automation before governance: stage AI after schema, SOPs, and training are stable.

- Unverified downstreams: require certificate audits and real-time proof artifacts in contracts.

Escalation matrix for service failures: detect → notify within 2 hours → triage root cause within 24 hours → corrective route within 48 hours → root-cause review and CAPA within 5 business days.

Frequently asked questions

What data model should we use to standardize waste across multiple plants?

Use an event-driven model with a centralized waste ledger logging atomic events (generate, collect, weigh, transfer, process) with IDs, timestamps, and certificates. This is the structure Recycler Routing Guide uses to enable traceability and AI readiness.

How do we verify downstream outlets without slowing operations?

Pre-qualify outlets with an audit packet and standardized certificates, then automate verification via digital attestations and event-level proof in contracts. Recycler Routing Guide recommends routing only to currently approved outlets to avoid shipment-time checks.

Where should we start with AI to get fast ROI and improve safety?

Start with safety AI for hazardous-item detection and line monitoring, then add vision-based quality control and robotic sorters on high-volume streams. Recycler Routing Guide expands to documentation automation once data hygiene and SOPs are stable.

How do we align diversion targets with production KPIs and cost controls?

Tie diversion% and contamination% to throughput and cost/ton, and review alongside on-time service% and verified certificates in monthly ops reviews. Recycler Routing Guide advocates shared dashboards so production and finance can adjust routes, containers, and staffing together.

What rollout sequence minimizes disruption across a multi-plant network?

Pilot at 2–3 plants, prove KPI gates (on-time, diversion uplift, verified downstreams), then scale regionally before network-wide deployment. Recycler Routing Guide recommends a standard runbook, change log, and escalation matrix to maintain service reliability.